- Stay

- What's On

- Things To Do

- Food & Drink

- Explore

- Inspiration

- Offers

- Weddings

- Blog

My Planner

- Stay

- What's On

- Things To Do

- Food & Drink

- Explore

- Inspiration

- Offers

- Weddings

- Blog

You are here: Explore > Famous People > David and Robert Mushet

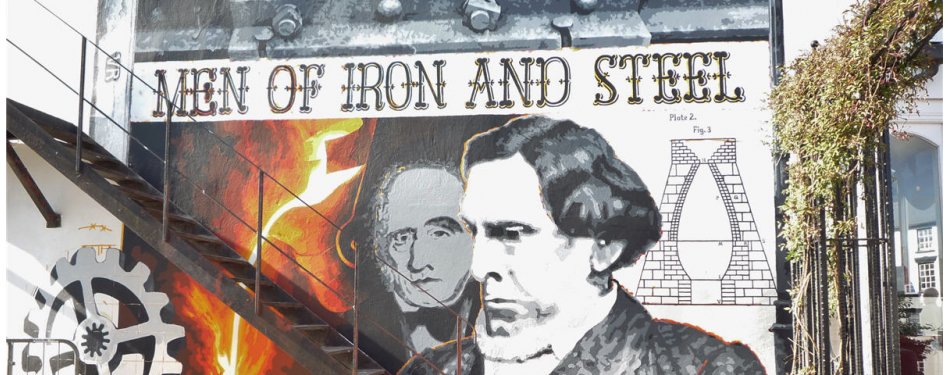

In the first half of the 19th century significant developments in the production of iron and steel took place in Coleford, the work of father and son metallurgists, David and Robert Mushet.

In the first half of the 19th century significant developments in the production of iron and steel took place in Coleford, the work of father and son metallurgists, David and Robert Mushet.

David Mushet, a Scot, came to Coleford in 1810 to operate the new coke-fired Whitecliff furnace. Whitecliff was not a success but Mushet built up considerable investments in the area. David and his wife Agnes lived at Tump House in Coleford. Their 7th child Robert Forester Mushet was born here in 1811 and he lived here in later life with wife Mary Ann and family including their 3rd child, Mary who was born in 1850.

David Mushet had interests in coal and iron mines around Coleford and at Dark Hill had a brick works. In 1818 he built a coke fired iron furnace here. The Dark Hill works were mainly used for large scale experiments, rather than production, and over the next 20 years Mushet perfected the production of a superior iron more malleable and suitable for tinplate by direct smelting rather than post-refining.

Steel had long been made by repeatedly heating iron and beating out impurities but in the 19th century a cheap method suited to mass production was sought. That work was done at Dark Hill by the Mushets but others got the credit.

In 1845 the Dark Hill works passed to Mushet's 3 sons; David died in 1847 and is buried in the churchyard at Staunton. Robert became manager but it was an uneasy relationship with his brothers. Robert took out 54 patents on the work done by him and his father but didn’t have the finances or business skill to benefit from them.

In the first years of railways the rails were short-lived (3 to 5 months) but Robert developed more durable rails meaning that less maintenance was needed. Robert Mushet made steel rails at Dark Hill (actually the ingots were made and then rolled in Ebbw Vale) that were installed at Derby station (Midland Railway) in 1857. They showed no wear for 10 years during which there 700 train movements a day and were not scrapped until 1873. As well as the rails, Robert developed self-hardening (tungsten) steel needed for drills and machine tools.

Robert investigated the Bessemer Process which in 1848 produced poor quality steel. He improved the process by burning off impurities and introducing carbon and manganese. This had the effect of improving the quality of the finished product, increasing its malleability – its ability to withstand rolling and forging at high temperatures.

“I saw then that the Bessemer process was perfected and that, with fair play, untold wealth would reward Mr. Bessemer and myself..."

Mushet's dream was never to be fulfilled. Bessemer came to Coleford to learn what had been done. While others made fortunes from Robert Mushet's discoveries, he failed to capitalise on his successes and by 1866 was destitute and in ill-health. In that year his 16 year old daughter, Mary, travelled to London alone, to confront Bessemer at his offices, arguing that his success was based on the results of her father’s work at Coleford. Bessemer, whose own process for producing steel was not economically viable without Mushet's method for improving quality, decided to pay Mushet a lump sum of £377 14s 10d (to cover his debts) and an annual pension of £300, a very considerable sum, which he paid for over 20 years; possibly with a view to keeping the Mushets from legal action.

Henry Bessemer was knighted in 1879 – a letter in the Times stated that Robert Forester Mushet should have been similarly honoured. Robert died at Cheltenham in 1891 and is buried with his wife and daughter, Mary, in Cheltenham Cemetery.

©Visit Dean Wye 2025. All Rights Reserved.

*Visit Dean Wye is the trading name of Forest of Dean & Wye Valley Tourism Limited.